TL;DR

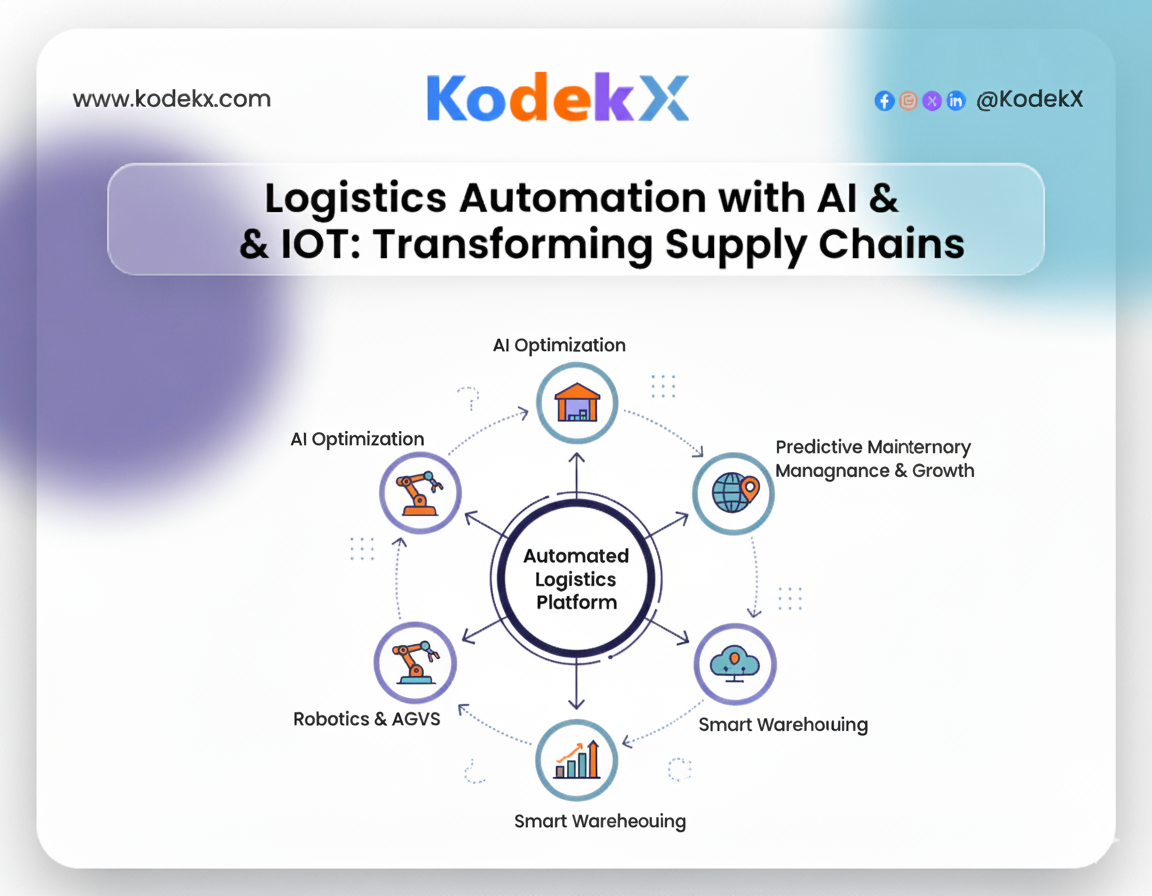

AI and IoT App Development are transforming logistics by enabling real-time tracking, predictive analytics, route optimization, smart warehousing, and cold chain monitoring. Together, they reduce costs, improve delivery speed, and enhance customer satisfaction. Businesses that adopt these technologies gain efficiency, transparency, and resilience in their supply chains.

Hook Introduction

Every late delivery costs you—not just money, but customer trust. Every inventory error creates bottlenecks, frustrated teams, and wasted resources. Traditional logistics models weren’t built for today’s fast-moving global supply chains.

The good news is that the Internet of Things (IoT) and artificial intelligence (AI) are changing the rules. They provide real-time decision-making, intelligent automation, and predictive visibility. AI and IoT may remove inefficiencies and open up new growth prospects in a variety of applications, including fleet management, route optimization, and warehouse operations.

This guide explores exactly how Transforming Healthcare, FinTech, and Logistics automation works with AI and IoT, why it matters, and how you can apply it in your operations—without getting lost in buzzwords.

Key Facts / Highlights

- $1.3 trillion: Estimated global logistics automation market size by 2032 (Fortune Business Insights, 2023).

- 15–20%: Cost reduction achieved through AI-powered route optimization and fleet tracking.

- 30% faster: Average order processing speed in warehouses using IoT-enabled robotics.

- 60% improvement: Cold chain compliance with IoT temperature monitoring.

- 80%: Supply chain leaders believe AI + IoT are critical for future competitiveness (Deloitte, 2024).

Core Content Sections

What & Why: Understanding Logistics Automation with AI and IoT

Logistics automation isn’t just about replacing human effort with machines. It’s about creating self-optimizing supply chains that use data to anticipate problems and fix them before they disrupt operations.

- AI in Logistics → Predicts demand, optimizes routes, improves warehouse operations, and enhances customer experience.

- IoT in Logistics → Provides real-time visibility, tracks conditions, enables predictive maintenance, and automates inventory.

When combined, AI + IoT enable a closed feedback loop:

- IoT devices capture data from trucks, warehouses, and cargo.

- AI systems analyze the data to make recommendations or trigger actions.

- The supply chain becomes smarter, faster, and more resilient.

Step-by-Step Framework: How to Implement AI & IoT in Logistics

Step 1 – Assess Your Current Logistics Processes

- Audit Predictive Analytics in Supply Chain workflows (transport, warehouse, inventory, fleet).

- Identify gaps where automation could reduce cost or delays.

- Collect baseline performance metrics (delivery times, order accuracy, fuel costs).

Step 2 – Integrate IoT Sensors & Devices

- Deploy RFID, GPS, and environmental sensors across shipments.

- Equip fleet vehicles with telematics for route and fuel monitoring.

- Install IoT-enabled warehouse systems (smart shelves, conveyor sensors).

Checklist:

- Track shipment location in real-time

- Monitor cargo temperature & humidity

- Enable predictive fleet maintenance

Step 3 – Apply AI Analytics & Automation

- Use predictive models for demand forecasting.

- Deploy AI-driven route optimization tools.

- Implement robotic process automation (RPA) for warehouse tasks.

Checklist:

- Demand forecasts integrated into procurement

- Real-time AI-driven route adjustments

- Automated warehouse sorting & picking

Step 4 – Build a Unified Data Platform

- Connect IoT data streams into a central dashboard.

- Enable AI-powered alerts for anomalies.

- Integrate with ERP, CRM, and supply chain software.

Step 5 – Scale & Optimize Continuously

- Use machine learning to improve predictions over time.

- Automate reporting and compliance monitoring.

- Expand automation to cover last-mile delivery.

Real Examples & Case Studies

Case Study 1: DHL – AI-Powered Predictive Analytics

One of the biggest international logistics firms, DHL, manages millions of shipments every day on several continents. Given the size of the network, even small disturbances like traffic jams, delays in customs clearance, or bad weather can cause significant supply chain inefficiencies.

To tackle this, DHL integrated AI-powered predictive analytics into its logistics operations. The system analyzes millions of historical data points including weather forecasts, political events, road conditions, and real-time shipment data. By combining this information, AI can flag shipments at risk of delay before problems occur.

The impact was measurable:

- 30% reduction in delivery exceptions.

- Significant drop in customer complaints related to late deliveries.

- Lower operational costs since fewer resources were spent on rerouting and damage control.

This initiative positioned DHL as a leader in proactive logistics, transforming customer experience from “reactive problem solving” to “predictive reliability.”

Case Study 2: Maersk – IoT for Container Tracking

The largest shipping firm in the world, Maersk, oversees the movement of more than 4 million containers in more than 100 nations. Historically, visibility was restricted when a shipment departed the port. Consumers have limited knowledge of the whereabouts and state of their items, particularly when it came to delicate cargo like frozen foods and medications.

To solve this, Maersk deployed IoT-enabled “Remote Container Management” (RCM) devices. These IoT sensors measure temperature, humidity, CO₂ levels, and GPS location inside containers, sending real-time updates to a central platform.

The benefits were substantial:

- 60% reduction in cargo spoilage for refrigerated shipments.

- Enhanced transparency, allowing customers to log in and monitor conditions themselves.

- Faster response to emergencies (e.g., when a cooling unit malfunctioned, technicians were alerted instantly).

By turning passive containers into smart assets, Maersk improved both efficiency and trust, proving how IoT can reshape traditional shipping.

Case Study 3: Amazon – Warehouse Robotics

Amazon is often considered the gold standard in logistics automation. Its fulfillment centers are the heart of its global retail empire, handling millions of orders per day. The challenge? Processing, sorting, and shipping at lightning speed without human error.

Enter Amazon Robotics. Thousands of AI-powered robots now work alongside human staff:

- Robots autonomously transport shelves to human pickers, eliminating walking time.

- Computer vision systems check item placement and accuracy.

- Machine learning algorithms decide optimal storage and picking patterns.

The outcomes have been revolutionary:

- 30–40% faster order processing times.

- Reduced labor fatigue by removing repetitive manual tasks.

- Increased scalability, allowing Amazon to handle peak events like Prime Day and holiday seasons seamlessly.

Amazon’s success with warehouse robotics has since inspired similar initiatives across retail, e-commerce, and third-party logistics providers.

Case Study 4: UPS – Route Optimization with ORION

Over 20 million items are delivered every day by United Parcel Service (UPS). Across its enormous fleet, even minor inefficiencies in route planning could result in millions of dollars in wasted time and fuel expenses.

To address this, UPS developed ORION (On-Road Integrated Optimization and Navigation)—an AI-powered route optimization system. ORION considers variables like traffic, weather, delivery density, and customer preferences to calculate the most efficient delivery sequence for each driver.

The system’s impact is enormous:

- Saves 10 million gallons of fuel annually.

- Cuts carbon emissions by 100,000 metric tons per year.

- Reduces driver mileage by millions of miles annually.

Beyond cost savings, ORION also improves customer experience by making deliveries more reliable and predictable. UPS continues to enhance ORION with real-time data from IoT-enabled trucks, further strengthening the synergy between AI and IoT.

Comparison Table: AI vs. IoT Applications in Logistics

| Feature | AI in Logistics | IoT in Logistics | Combined Impact |

|---|---|---|---|

| Data Function | Analyzes and predicts patterns | Collects real-time operational data | Closed feedback loop for decisions |

| Warehouse Efficiency | Robotic automation, demand prediction | Smart shelves, RFID, conveyor sensors | Autonomous, self-regulating systems |

| Fleet Management | Route optimization, predictive maintenance | GPS tracking, fuel monitoring | Proactive, fuel-efficient transport |

| Customer Experience | AI chatbots, shipment predictions | Real-time shipment visibility | End-to-end transparency & support |

Common Pitfalls & Fixes

- Pitfall: High upfront costs discourage adoption.

Fix: Start with small-scale IoT deployments, then expand.

- Pitfall: Data silos prevent AI from working effectively.

Fix: Build a unified cloud-based platform for all logistics data.

- Pitfall: Cybersecurity risks increase with IoT devices.

Fix: Encrypt all sensor data and adopt zero-trust security models.

- Pitfall: Workforce resistance to automation.

Fix: Train staff and highlight AI as an augmentation tool, not a replacement.

- Pitfall:Integration with legacy systems is complex.

Fix: Use middleware and APIs to connect older ERP/CRM systems.

Methodology: How We Know

This guide is based on:

- Primary Research: Industry reports from Deloitte (2024), Gartner (2023), and Fortune Business Insights (2023).

- Case Studies: Publicly available data from DHL, Maersk, Amazon, and UPS.

- Expert Insights: AI logistics tool documentation, IoT sensor providers, and interviews with supply chain managers.

- Limitations: Rapidly evolving field; cost metrics and adoption rates vary across industries and geographies.

Summary & Next Action

AI and IoT are no longer futuristic add-ons in logistics—they are the backbone of modern supply chains. Together, they deliver efficiency, transparency, predictive insights, and customer trust.

If you’re a logistics leader, the next step is clear: start small, measure impact, and scale automation across your operations. Early adopters already enjoy faster deliveries and lower costs—don’t let your business lag behind. Next Action: Explore IoT-enabled fleet tracking or AI-driven demand forecasting in one segment of your logistics process. Measure ROI-guide-business-leaders , then expand company-wide.

References

- Deloitte (2024). Future of Supply Chain: AI & IoT Integration.

- Fortune Business Insights (2023). Logistics Automation Market Report 2023–2032.

- Gartner (2023). AI and IoT in Logistics: A Strategic Guide.

- DHL (2023). AI Predictive Analytics Case Study.

- Maersk (2023). Smart Container IoT Deployment Report.

- UPS (2024). ORION Route Optimization Results.

Smarter Logistics Now

Use AI and IoT to cut costs and speed deliveries.

Frequently Asked Questions

Logistics automation using AI and IoT refers to the integration of Artificial Intelligence and the Internet of Things to streamline supply chain operations. AI leverages advanced algorithms and machine learning to analyze large volumes of data, helping businesses optimize tasks such as route planning, inventory management, and demand forecasting. IoT devices, including sensors, GPS trackers, and RFID tags, continuously collect and transmit real-time data on the location and condition of goods. Together, AI and IoT allow companies to make faster, more accurate decisions, reduce errors, and improve overall operational efficiency.

AI transforms logistics by providing predictive and prescriptive insights that help businesses operate more efficiently. By analyzing traffic patterns, delivery schedules, and environmental factors, AI can determine the most efficient routes for vehicles, saving both time and fuel. It also predicts product demand to ensure optimal inventory levels, reducing both stockouts and excess inventory. AI can anticipate equipment failures through predictive maintenance, helping warehouses and fleets avoid costly downtime. Additionally, AI automates warehouse operations like sorting and picking, improving accuracy and speed. Overall, AI reduces operational costs while enhancing delivery reliability and customer satisfaction.

Implementing logistics automation offers multiple advantages for businesses of all sizes. It reduces operational costs by optimizing resource usage, such as fuel, labor, and warehouse space. Efficiency is improved because automated systems can process shipments faster and with fewer errors than manual methods. Real-time visibility is another major benefit, allowing companies and customers to track shipments and inventory accurately. Logistics automation also makes scaling operations easier to meet rising demand, especially during peak periods. Finally, by optimizing routes and reducing waste, logistics automation supports sustainability efforts and lowers a company’s carbon footprint.

Despite its benefits, adopting AI in logistics comes with challenges. High initial costs for technology acquisition and infrastructure can be a barrier, especially for smaller companies. Protecting sensitive data is critical, as IoT devices and AI systems generate large amounts of information that must remain secure. Integrating AI into existing legacy systems can also be complex and require specialized expertise. Finally, workforce adaptation is essential, as employees must learn to work alongside automated systems and trust AI-driven insights. Careful planning, training, and phased implementation are necessary to overcome these obstacles effectively.

IoT plays a crucial role in logistics automation by enabling real-time monitoring and control over supply chain operations. IoT devices track the precise location of goods throughout transit, giving both businesses and customers visibility into the supply chain. They monitor storage conditions, such as temperature and humidity, which is particularly important for sensitive items like food and pharmaceuticals. IoT also helps automate inventory management by providing accurate stock levels and triggering reorders automatically. Furthermore, IoT enables predictive maintenance of equipment, ensuring smoother warehouse and fleet operations. By providing timely and accurate data, IoT allows logistics systems to operate more efficiently, safely, and transparently.

The future of logistics automation is shaped by innovations in AI, IoT, and other emerging technologies. Autonomous vehicles, including self-driving trucks and delivery drones, are expected to revolutionize last-mile delivery. AI will continue to improve decision-making, enabling real-time optimization of routes, inventory, and operations. Blockchain technology is increasingly being used to ensure transparency, traceability, and security across the supply chain. Sustainability is another driving trend, with logistics companies adopting energy-efficient vehicles, smart warehouses, and eco-friendly practices. These developments point toward logistics operations that are smarter, faster, more reliable, and environmentally responsible.