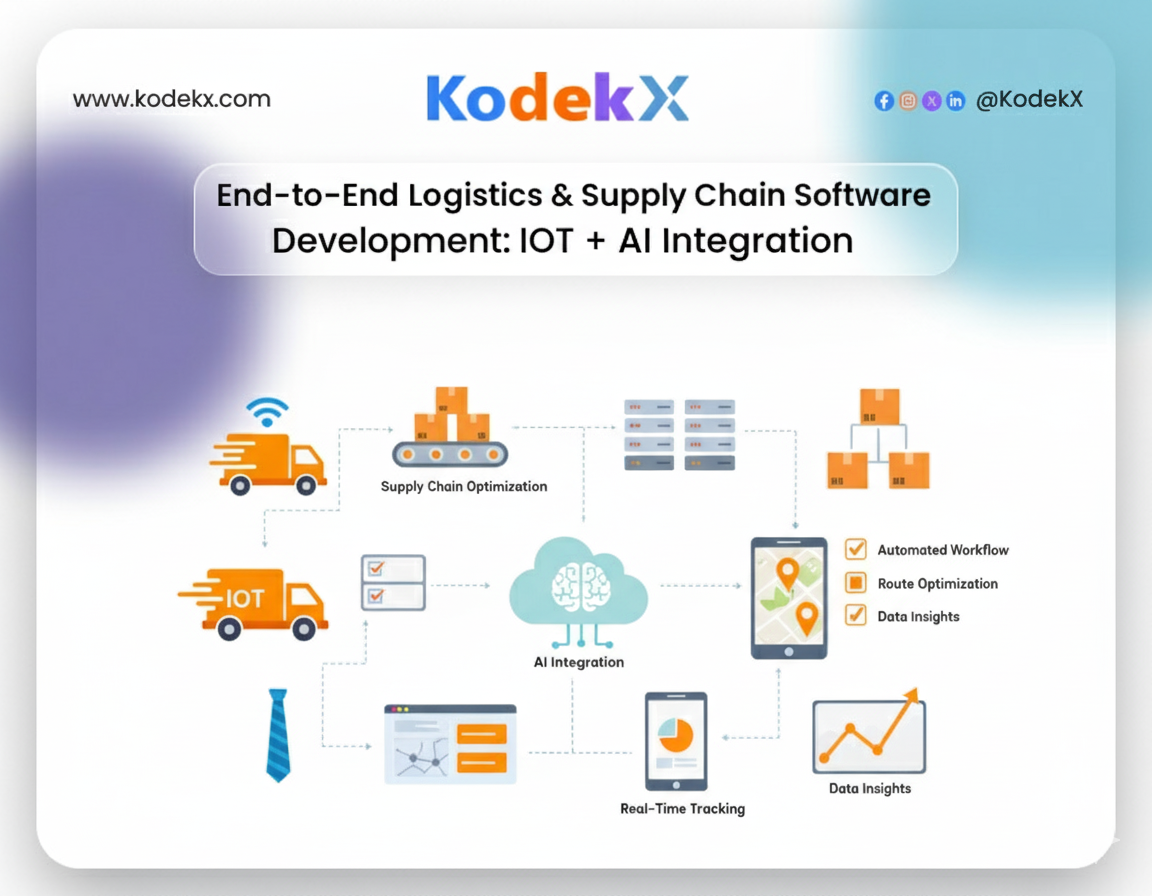

Imagine this: you’re the operations lead at a fast-growing e-commerce company. You feel blind when shipments leave your warehouse—no real-time alerts on delays, damage, or route deviations. You want software that ties together trucks, inventory, demand forecasts, supplier risk, and live IoT App Development data into one system.

That’s exactly what end-to-end logistics & supply chain software with IoT + AI integration promises—and delivers, when built right.

In this article, you’ll learn how to design, build, deploy, and scale that kind of system. You’ll see real pitfalls (and cures), case studies from brands, and a clear methodology you can follow. By the end, you’ll understand how to move from isolated tools to a unified, intelligent logistics platform.

TL;DR / Quick Answer

End-to-end logistics & supply chain software with IoT + AI integration means combining hardware (sensors, devices, networks) and intelligence (ML, inference, predictive models) in one unified system. Get visibility, forecasting, anomaly detection, and optimization in real time. The main success factors are scalable architecture, clean modular design, data pipelines, edge-to-cloud coordination, and rigorous testing/regulation design.

Key Facts (2023–2025)

- The global SCM software market is projected to grow at ~14.6% CAGR from 2025 to 2029, driven by supply chain visibility and AI features (Technavio) (2025).

- The global industrial software market (which includes logistics, IoT, optimization) reached $146 billion in 2023 and is forecast to grow ~12% in 2024 (IoT Analytics) (2024).

- The global AI in logistics market was valued ~$17.96 billion in 2024 and is expected to grow rapidly (Precedence Research) (2024).

- IoT Analytics forecasts 18.8 billion connected devices globally by end of 2024 (growing ~13%) (2024).

- In McKinsey’s 2024 supply chain leader survey, 73% of companies reported progress in dual-sourcing strategies and 60% have visibility into tier-1 suppliers (2024).

Why Build End-to-End Logistics Software Integrating IoT + AI

When you piece together fragmented tools—TMS, WMS, ERP, demand forecasting, telematics—you often lose consistency, context, and real-time responsiveness.

Benefits of Unified Logistics Software

- See the full flow: from supplier to factory to distribution to last mile, in a unified dashboard.

- React in real time: anomalies, route deviations, and temperature drifts trigger automated alerts.

- Predict proactively: forecast demand surges, supply shortages, and maintenance needs.

- Optimize continually: dynamic route planning and capacity scheduling improve over time.

This solves the pain point of blind spots in logistics—where issues cascade unnoticed until it’s too late.

Building this kind of system merges hardware, connectivity, big data, AI, and compliance — but it’s now a competitive necessity. KPMG calls the “smart Predictive Analytics in Supply Chain” the new normal (KPMG, 2024).

Many competitors only build point solutions (like fleet tracking), which leaves gaps and integration headaches. A full-stack, edge-to-cloud system encodes your domain logic directly into your platform—giving you a strategic advantage.

Architecture & Core Components

To build a reliable IoT + AI-integrated logistics & supply chain platform, use a layered architecture balancing modularity, responsiveness, and scalability.

Data & Connectivity Layer

- Edge devices & gateways: sensors on trucks (GPS, accelerometer, temperature), RFID tags, BLE beacons.

- Connectivity protocols: NB-IoT, LoRaWAN, LTE/5G, WiFi, MQTT, OPC-UA.

- Edge processing: microcontrollers perform filtering and anomaly detection before cloud upload.

Ingestion & Stream Pipeline

- Devices stream telemetry via Kafka or MQTT brokers.

- Stream processors (Flink, Spark Streaming) clean and aggregate data.

Storage & Data Lake

- Cold data: time-series databases (InfluxDB, AWS Timestream).

- Warm/hot data: OLAP or relational stores (Snowflake, ClickHouse).

- Metadata registry: maintains asset relationships and configurations.

AI / Analytics Layer

- Descriptive: dashboards and KPIs.

- Predictive: forecasting and delay prediction.

- Prescriptive: route and inventory optimization.

- Anomaly detection: unsupervised ML models.

Business Logic Layer

- Core modules for shipments, procurement, and supplier management.

- API-driven microservices (Node, Python, Go).

- Workflow orchestration via Airflow or Temporal.

UI & Dashboard

- Web portals for planners, mobile apps for drivers.

- Includes alerts, simulation mode, and exception handling.

Security & Compliance

- Secure device identity (X.509, TPM), encrypted communication, role-based access.

- Meets transportation and customs compliance.

Integration Layer

- API/EDI connectors to ERP, WMS, or TMS systems.

- Future-proof with plug-ins for drones or autonomous fleets.

Example: Architecture Table

| Layer | Purpose | Key Technologies / Responsibilities |

|---|---|---|

| Edge / Connectivity | Capture & preprocess IoT signals | NB-IoT, LoRaWAN, MQTT, edge filtering |

| Ingestion | Stream & queue data | Kafka, MQTT brokers, streaming engines |

| Storage | Store time series & relational | InfluxDB, ClickHouse, data warehouse |

| Analytics / AI | Forecast, detect, optimize | ML models, optimization, anomaly detection |

| Business Logic | Domain-specific modules | Microservices, rule engine, workflow |

| UI / Client | Interface for users & agents | Web UI, mobile apps, dashboards |

| Security & Integration | Safe communication & extensibility | Auth, encryption, RBAC, APIs & connectors |

Development Phases & Implementation Steps

Phase 1: Proof of Concept & MVP

- Target a single domain slice (e.g., outbound delivery).

- Instrument a few assets with IoT sensors.

- Build ingestion, SaaS Admin Dashboard, and alert pipeline.

- Integrate with ERP/WMS data.

Phase 2: Expand & Modularize

- Scale coverage to multiple sites and fleets.

- Introduce predictive models for demand or route delay.

- Implement exception handling and workflow automation.

Phase 3: Intelligent & Autonomous Stage

- Add prescriptive optimization and digital twin simulations.

- Deploy edge ML for faster inference.

- Integrate external partners (carriers, providers).

Phase 4: Optimization & Governance

- Fine-tune performance, autoscale resources.

- Apply data governance and compliance frameworks.

- Monitor model drift and retrain regularly.

Deliver incremental value per phase—measure KPIs like on-time delivery, cost reduction, and inventory turnover.

Common Pitfalls & Fixes

1. Overengineering Too Early

- Mistake: Building all features before validating MVPs.

- Fix: Launch a focused MVP, test, and expand modularly.

2. Sensor Noise & Calibration Issues

- Mistake: Trusting raw sensor data.

- Fix: Add calibration and anomaly filters.

3. Network Congestion & Latency

- Mistake: Sending all IoT data unfiltered to cloud.

- Fix: Process at edge and batch-transmit data.

4. Tight Coupling Between Modules

- Mistake: Monolithic system structure.

- Fix: Adopt microservices and versioned APIs.

5. Model Drift

- Mistake: Static AI models degrade over time.

- Fix: Retrain periodically and include human oversight.

6. Weak Security Posture

- Mistake: Insecure device authentication.

- Fix: Use X.509 certificates, TPM chips, mutual TLS.

7. Ignoring Scalability Early

- Mistake: Underestimating load and redundancy.

- Fix: Build for autoscaling and disaster recovery.

8. Version Control & Change Management Failures

- Mistake: Uncoordinated updates breaking integrations.

- Fix: Implement versioning and feature flags.

Real-World Case Examples

DHL Resilience360 & IoT Monitoring

DHL’s Resilience360 integrates supplier risk and IoT signals (weather, port delays) for predictive disruption management. The system enabled DHL to reroute up to 20% of delayed shipments, increasing resilience.

Maersk + IBM TradeLens Collaboration

Maersk’s blockchain-IoT hybrid, TradeLens, tracks container conditions globally. AI-driven port congestion insights reduced dwell time by 8–10% and improved customs transparency.

Amazon Robotics & Route Optimization

Amazon integrates warehouse robotics and AI-driven routing to maintain throughput during peaks. The system dynamically assigns robotic tasks and routes for efficiency.

Tesla Gigafactory Digital Twin

Tesla uses IoT sensors and AI forecasting to connect its production, parts, and logistics. Their digital twin approach ensures inventory balance and uptime across facilities.

Methodology

Tools Used

- Industry and academic literature (MDPI, IEEE)

- Reports from Technavio, McKinsey, KPMG, IoT Analytics

- Technical whitepapers on IoT architecture and AI modeling

Data Sources

- IoT Analytics industrial market studies

- SCM software market reports (Technavio, TBRC)

- AI-in-logistics growth data (Precedence Research)

- Global supply chain leader surveys (McKinsey)

Limitations & Verification

- Some case metrics are self-reported by companies.

- Market forecasts vary by methodology.

- Triangulation ensures credible synthesis from multiple independent reports.

Actionable Conclusion

You now have a clear blueprint to build end-to-end logistics & supply chain software integrating IoT and AI—from system design to PostgreSQL & Aurora Scaling Playbook. Global leaders like DHL, Maersk, and Tesla already prove its business impact. Start small: pick one workflow, instrument assets, and connect IoT + AI pipelines. Scale iteratively for maximum ROI. Ready to start building your logistics intelligence platform? Begin with an MVP that connects one warehouse-to-delivery flow and unlocks visibility in 90 days.

References

- IoT Analytics. “The Industrial Software Market Landscape: 7 Key Statistics Going Into 2025.” IoT Analytics, 2024.

- Technavio. “Supply Chain Management (SCM) Software Market to Grow by USD 24.87 Billion from 2025–2029.” PR Newswire, 2025.

- Precedence Research. “Artificial Intelligence (AI) in Logistics Market Size and Growth 2025 to 2034.” Precedence Research, 2024.

- KPMG. “Supply Chain Trends 2024: The Digital Shake-up.” KPMG, 2024.

- McKinsey & Company. “McKinsey Global Supply Chain Leader Survey 2024.” McKinsey & Company, 2024.

Smarter Supply Chains with AI

Optimize logistics with IoT-driven insights.

Frequently Asked Questions

A TMS focuses on routing and freight management, while a WMS optimizes warehouse operations. An end-to-end platform unites both—covering procurement, inventory, transportation, and supplier visibility.

Use edge processing for low-latency events or unstable connectivity, and cloud for deep analytics. Hybrid models often balance both effectively.

Yes. Even small companies benefit from predictive delivery models or stock-out prevention. Start with limited use cases and expand gradually.

Run diagnostics, monitor variance, and schedule recalibration cycles. Use fallback estimates when devices fail.

Early stages can leverage integrators or open-source tools, but long-term scalability requires internal IoT and AI specialists for reliability and IP control.